The Challenge

Valdese Weavers, one of the world’s largest jacquard fabric manufacturers, was looking for ways to remain competitive in an industry that had seen many companies fall victim to stiff offshore competition. Company leadership was determined to develop a long-term strategy that would help the manufacturer not only survive in a competitive environment, but also thrive as a market leader.

Internal processes needed to be examined and refined, and the company culture needed to evolve to a continuous improvement mindset. Who within the company had the training and time to guide this transformation?

Transportation costs needed to be brought under control, both on inbound shipments from vendors and outbound shipments to customers. Who within the organization had the necessary logistics expertise?

Leadership needed visibility to key performance indicators (KPIs) to measure success and pinpoint opportunities for improvement. How would the organization capture and manage the data?

Accounting needed help tracking down freight invoices and making sure the company was paying an accurate amount for their freight moves. Who knew what the company was to pay for the freight, and how would they audit the thousands of invoices?

Seeing the multi-layered challenge as one that could potentially erode the company’s revenues and threaten its survival, the company looked to Transportation Insight for strategic guidance.

The Solution

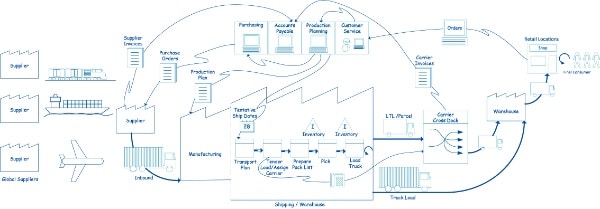

Understanding the complexity of the challenges Valdese Weavers faced, Transportation Insight constructed a customized, comprehensive solution based on its Extended LEAN® methodology that broadened the use of traditional LEAN principles to the company’s value chain. Each component of the solution was designed to seek out and remove non-value added activities, whether within the company’s four walls or throughout the supply chain.

To eliminate wasted effort, time and resources both inside the company and beyond the shipping and receiving docks, Transportation Insight:

- Implemented a state-of-the-art Transportation Management System (TMS) to give Valdese Weavers’ purchasing department and vendors alike the power to reduce freight costs by routing as many inbound shipments as possible on the least-cost carrier

- Helped reduce outbound Parcel costs by negotiating cost-effective Parcel carrier agreements

- Provided actionable business intelligence reporting to help leadership monitor KPIs

- Audited and paid freight invoices to significantly reduce overcharges

- Applied specific GL coding rules to freight invoices, reducing non-value-added administrative time for the accounting department

- Aided in the development of LEAN leaders throughout the company to foster a shift to a continuous improvement culture across the organization

- Assisted the company in developing a purchasing strategy to reduce costs on many indirect materials such as Maintenance, Repair and Overhaul supplies, printed material and packaging

The Results

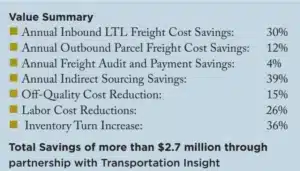

The immediate results brought by Extended LEAN helped Valdese Weavers shave time and cost from its day-to-day supply chain processes. The results also accelerated the company’s return on strategic investment in implementing traditional LEAN practices throughout its four locations. Extended LEAN created a shared competitive advantage for Valdese Weavers and its supply chain partners. Through collaborative efforts to refine processes with vendors and customers, these companies maximized the value delivered to customers while capturing a dominant portion of their respective markets.

With the savings realized through supply chain optimizations, Valdese Weavers could invest significantly in the long-term development and training of internal LEAN leaders by partnering with Total Insight, the LEAN Performance consulting division of Transportation Insight. The company developed a purchasing strategy in collaboration with United Sourcing Alliance, a division of Transportation Insight focused on strategic sourcing of indirect materials, to remove significant indirect expenses from its operations. While Valdese Weavers continued to work extensively on refining internal processes, Transportation Insight used its supply chain expertise to continue the elimination of waste beyond the company’s four walls.

Companies adopting the Extended LEAN approach are seeing dramatic results earlier in their LEAN journey and are getting the attention of executives who typically judge results by the impact on the bottom line within relatively short time horizons. As one of only three major decorative fabric manufacturers left in the United States, Valdese Weavers has embraced the Extended LEAN methodology to reduce its costs, improve its operational productivity and double its size, expanding its role as a major player in its industry.

“Extended LEAN has absolutely helped us improve every facet of our business. The process improvements we have achieved throughout our supply chain and within our operation have enabled us to reduce our costs and double our sales in the last decade.”

Carson Copeland, Chief Operating Officer, Valdese Weavers, Inc.